How thick should a beam be

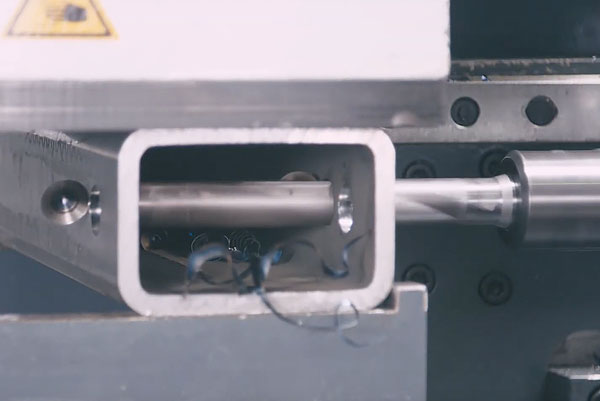

CNC Beam Drill Line not only processes beams and columns but can also easily process all steel profile including channel, flat, flat, base plates RHS, square and round.

Voortman technicians will complete the installation and calibration of your machine. After that, he'll spend time with operators and guide them through our comprehensive training program. Training will be given to your operators in: